Olive Harvesting – Tips for Harvesting Olives

The start of the harvest depends on the processing method, i.e., whether they will be used as table olives or for oil production.

| 1. Table Olives |

Fruits to be processed green are harvested when the deep green color fades to light green, and harvesting stops when the skin turns straw-colored.

Thus, for green olives, they are harvested while still unripe (before they even turn milky), towards late September to mid-October, depending on the variety and region.

Olives to be consumed as black olives are harvested later, when the flesh has blackened to a depth of up to 2/3, but before it starts to soften.

Only in special cases (throumbes, salted black olives) are the fruits allowed to overripen.

The characteristics of a good table olive are as follows:

Generally, the flesh-to-pit ratio is an important criterion for the quality assessment of a variety.

Based on this criterion, the higher the flesh content of a fruit relative to its pit, the greater its value is considered to be.

| 2. Oil-producing Olives |

The stage at which most fruits acquire a full black external coloration in irrigated crops is a reliable criterion for fruit collection for economical oil extraction, regardless of fruit size and current production.

However, in non-irrigated crops, using color change is not a sufficiently reliable criterion for harvesting.

In some varieties, it has been shown that oil accumulation in black ripe fruits is relatively small. Therefore, an earlier harvest, before the fruit's color fully changes, might be preferable because it reduces the risk of fruit damage from insects and production loss from fruit drop, and yields higher quality olive oil.

Furthermore, with mechanical harvesting, all fruits, regardless of ripening uniformity, are collected from the tree once. The speed of mechanical collection significantly shortens the harvesting period, so the collection time based on maximum oil accumulation is very important.

However, reliable criteria for calculating the end of the main olive oil accumulation period for each variety have not been determined.

Harvesting usually takes place in November-December, depending on the variety, region, and year.

Corfu is an exception (a high-rainfall area), where winter ends with heavy rains, and fruits are harvested from April to July, usually yielding very low-quality olive oil.

- Harvest Time

Harvest time plays a significant role in producing good quality olive oil.

Harvesting the fruit before physiological ripening will yield a smaller quantity of oil but high-quality olive oil.

Olive oil from unripe fruit is easily distinguished by its deep green color and the characteristic taste of freshness and “greenness” it imparts to the palate (agourelaio).

Low-quality olive oil is produced when overripe fruit is harvested.

For the production of aromatic oil, harvesting should be done at the beginning of the fruit ripening period, regardless of a small loss of oil.

Fruits that fall prematurely to the ground (hamades) due to infestations or drought should be collected first and not mixed with others because they yield lower quality oil.

- Harvest Season

The harvest season also affects the production of the following year.

When fruits remain on the trees for a long period, the trees' flowering the following year is quite limited.

When fruits are harvested green, or early during their ripening period for table use (but not after mid-October), then the production of the following year is greater than that of trees harvested later.

The timing and techniques of harvesting are also of great importance for reducing the olive fruit fly population.

Leaving fruits on the trees allows the olive fruit fly to continue its oviposition and reproductive activity between the end of one growing season and the beginning of the next, resulting in the development of a spring generation. For the same reason, collecting wild olive fruits from all neighboring trees is considered essential.

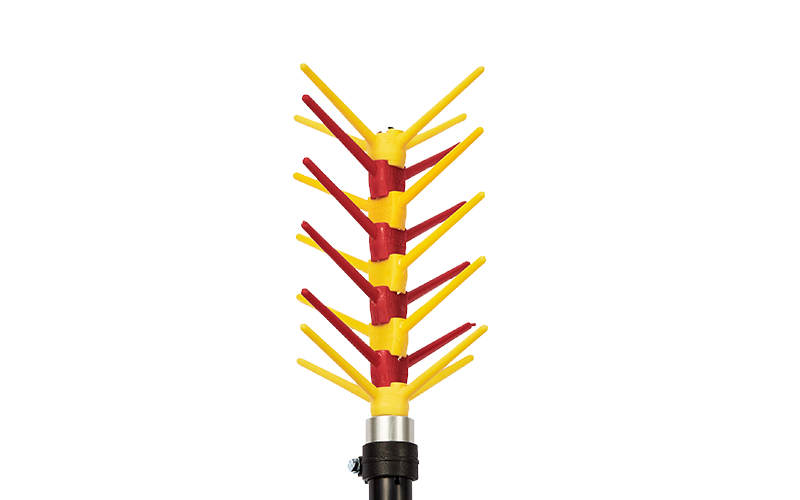

- Harvesting Methods

Fruits are harvested either by hand or mechanically.

Hand harvesting is applied to fruits intended for table use, to avoid damage and quality degradation (a time-consuming and very expensive process).

Mechanical harvesting is mainly used for oil-producing varieties.

The methods applied are:

The use of mechanical harvesting means allows for the harvesting of more trees in less time and with fewer laborers; tall trees are harvested more easily without the need for ladders, but care must be taken not to cause damage to the fruits and degrade their quality.

Also, some types of machinery have the disadvantage of cutting off part of the vegetation along with the fruits and creating wounds on the trees, which serve as entry points for pathogens.

For mechanical harvesters to be used, the fruits must be at the appropriate stage of ripeness and the trees must be shaped in a way that allows their use.

Furthermore, the use of shakers requires the olive grove to be on level ground.

Fruits must be harvested without impurities (leaves, wood, soil, etc.) and with as few impacts as possible.

It is recommended to use plastic nets, which are superior to canvas because they are cheap, easy to use, do not absorb liquids from broken fruits, are easily rinsed, and can be used in rainy weather.

However, there is an increased risk of theft.

- Storage – Preservation

After harvesting, the fruits are placed in plastic or wooden crates with holes, which ensure good ventilation and avoidance of high temperatures.

Another material is mesh bags, which also facilitate ventilation and prevent fungal growth.

Transporting fruit in plastic bags should be avoided.

The transport time to the destination (oil mill, processing plant) should be as short as possible.

If there is a delay in transporting the fruit to the oil mill, it should be spread in a thin layer 15-20 cm thick on a clean floor, where it can remain for up to one week without spoilage and degradation of olive oil quality.

Warehouses containing pesticides or petroleum products should under no circumstances be used for this purpose.

Pruning Machine Spare Parts

Pruning Machine Spare Parts Spare parts Koupepe

Spare parts Koupepe Wheeled Generator Spare Parts

Wheeled Generator Spare Parts Spare parts Asteras

Spare parts Asteras Spare parts Amolivo

Spare parts Amolivo